Automate Your Operations with Advanced AI-Driven Synthesis

We integrate intelligent systems into your production lines and business processes, unlocking unprecedented efficiency and resource optimization. Future-proof your operations today.

Trusted by Industry Innovators

See how we're transforming operations for leading manufacturers.

Partnering with Synthetix Operations was a pivotal moment for our company. Their AI integration has not only boosted our production efficiency by over 35% but has also given us predictive capabilities we never thought possible. The implementation was seamless, and their team provided exceptional support throughout the entire process. We now operate with a level of precision and foresight that sets us apart in the market.

Implementation & Support Tiers

Choose the plan that scales with your automation goals. Contact us for custom enterprise solutions.

Core

$2,500 /mo

Rocznie: $2,125

- Single Process Automation

- Core AI Analytics

- Standard Support

Advanced

$7,500 /mo

Rocznie: $6,375

- Multi-Process Automation

- Predictive Maintenance Module

- Priority Support

Enterprise

Custom /mo

Rocznie: Custom

- Full Facility Integration

- Dedicated AI Specialist

- 24/7 On-Call Support

Engineered for Industry Leaders

Our solutions are designed for enterprises ready to embrace the future of manufacturing and operations.

For Production Managers

Automate production lines, enhance quality control, and implement predictive maintenance to reduce downtime and increase throughput.

For Supply Chain Directors

Optimize inventory management, automate warehouse operations, and predict supply chain disruptions with our intelligent logistics modules.

For Executives

Gain real-time, data-driven insights into your entire operation. Make strategic decisions based on accurate performance metrics and predictive analytics.

For Plant Operators

Monitor and optimize energy consumption across your facilities. Our AI identifies inefficiencies and automates adjustments to reduce costs.

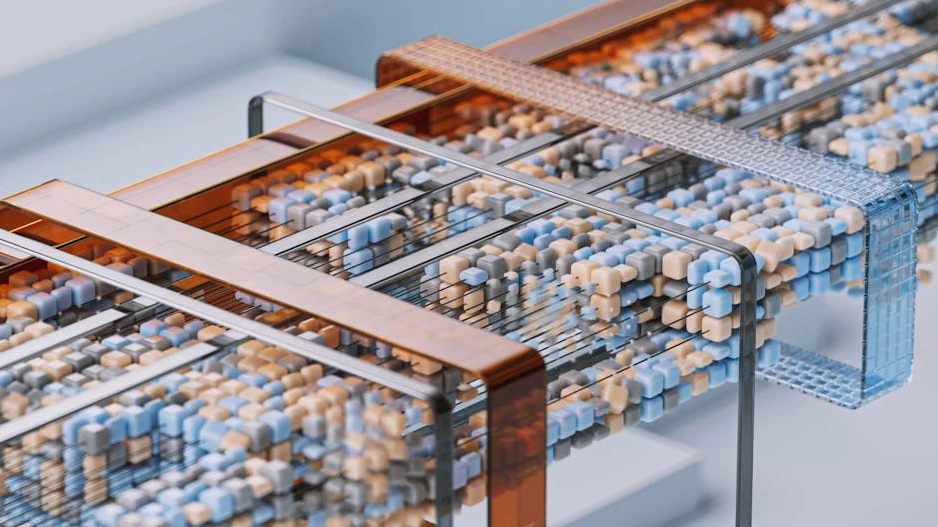

Core Components of Our AI Integration

Our platform is built on a robust technology stack designed for scalability, security, and seamless integration into your existing infrastructure.

Your Roadmap to AI-Powered Automation

We follow a structured, four-step process to ensure a smooth and effective integration of our AI solutions.

Initial Audit & Analysis

We begin with a comprehensive audit of your current operations to identify key areas for automation and efficiency improvements. This data-driven approach forms the foundation of our strategy.

Custom Solution Design

Our experts design a bespoke AI integration plan tailored to your specific needs, technological stack, and business goals. We create a detailed blueprint for implementation.

Seamless Implementation

Our engineering team deploys the AI models and automation protocols with minimal disruption to your ongoing operations. We handle the full integration cycle, from hardware setup to software configuration.

Continuous Optimization

Post-deployment, our system continuously learns and optimizes your processes. We provide ongoing support and performance monitoring to ensure you achieve maximum long-term value.

Common Integration Questions

Everything you need to know about implementing our AI solutions.

The timeline for implementation varies based on the complexity of your operations. A standard single-process automation can take 4-6 weeks from initial audit to full deployment. For comprehensive, multi-facility integrations, the process may extend to several months. We provide a detailed roadmap with clear milestones after the initial analysis, ensuring full transparency and alignment with your production schedules. Our goal is always to minimize disruption and deliver value as quickly as possible.

Data security is our highest priority. We employ end-to-end encryption for all data in transit and at rest. Our systems are housed in ISO 27001 certified data centers, and we adhere to strict access control protocols. All client data is logically separated and firewalled. We are fully GDPR compliant and conduct regular security audits to ensure your proprietary information remains confidential and protected against any potential threats. We are happy to provide detailed documentation on our security architecture.

Absolutely. Our platform is designed to be hardware-agnostic. We use a combination of IoT sensors, PLCs, and custom APIs to connect with a wide range of industrial equipment, both modern and legacy. During the audit phase, we conduct a thorough assessment of your existing technology stack to ensure seamless data collection and system compatibility. Our engineers specialize in creating robust integration layers that allow our AI to communicate effectively with your machinery without requiring a complete overhaul.

We offer tiered support packages to meet your specific needs. Our standard support includes access to our technical helpdesk and regular software updates. The priority support package provides faster response times and dedicated support channels. For our enterprise clients, we offer 24/7 on-call support with a dedicated AI specialist assigned to your account. Our commitment is to a long-term partnership, ensuring your automated systems continue to perform optimally and evolve with your business.

Still have questions? Speak with an expert.

Ready to Optimize Your Operations?

Schedule a complimentary audit with our AI specialists. We'll analyze your current processes and provide a detailed report on potential efficiency gains and cost savings.

- Identify key automation opportunities

- Receive a custom implementation roadmap

- Get a clear ROI projection